The manufacture of barrels in steel “DAMAS”

The Damas was, there is a little more than 100 years, in the area of Liège generator of work for thousands of workmen divided in hundreds of small rustic forging mills along the water being used as driving force.

The manufacture of the Damas at that time of almost all with the hand was not a small matter.

All starts with the "Lopin" which is a block made up of layers of iron and layers of steel divided well into checker work. This piece is heated and beaten in order to obtain a new more homogeneous block a length of approximately 60 cm and weighing several kilos.

This block again is heated and beaten on its four faces in order to obtain a thin rod from 7 to 8 mm of section. This reduction is obtained thanks to the aid of a rudimentary rolling mill named "the sheep".

It was then necessary to join together 3 to 6 rods "the blades" by twist with vigorous fire and hammering in order to obtain a flat of approximately 5 mm thickness on 25 mm of width. It. acte then of the "ribbon".

This ribbon was then rolled up on a chuck covered with a sheet shirt to facilitate the release from the mould. It was then necessary to heat with white this tube to weld it whorl by whorl by hammering it again and finally to obtain after good of work a metal tube. The barrel thus obtained was then entrusted to other specialists, to borer, to polisher and to bronzer who coated the finished gun of acid to emphasize the drawing of the Damas.

The manner of mixing the blades allowed equip blacksmiths inhabitant of Liège to create the wished drawings at will, such as: "damas crollé turc", "Oxford", "turc miné blanc", "crollé extra-fin", "étoilé", "Bernard", "Boston" etc.

The rather high prices of these barrels made develop the "Damas forgery" which was sometimes so well imitated that only a metallographic test made it possible to detect the truth of the forgery.

The technique employed that of "the etching"; acid was emptied on a stencil key set imitating the Damas and was placed on the gun. The acid tackled only the not covered places.

But only Damas truth could resist the hard tests. Arrived at the rupture limit by overload, the Damas does nothing but inflate thus warning the owner, while steel bursts literally.

The forging of the barrels in area of Liège decreased at the 20th century to disappear about 1930.

GG

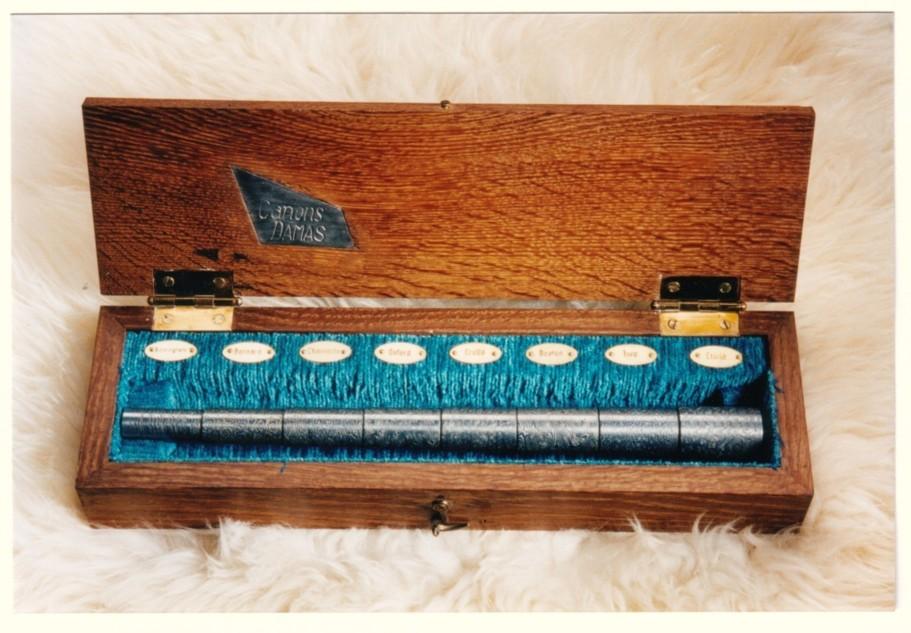

Box of barrel Damas.

This box of presentation in oak, decorated inside light blue velvet, contains a very beautiful part of control of the Masters of Liège gunners, namely a "Damas gun" with eight different decoration and decreasing diameters sections.

The manufacture of the Damas guns is a speciality which requires a long practice, a great experiment as well as the knowledge of some turns of hand for the preparation and the cooling of the steel bars entering their clothes industry.

The overall length of this piece is of 315mm, the higher diameter is of 25mm while the inferior is of 15mm.

With the presentation of this box, the future purchaser of weapon Damas a gun had all the leisure to choose on part the drawing of the Damas which it wished to see being reproduced on his weapon.

These eight Damas were different by evocative names such as "CROLLE, BOSTON, BIRMINGHAM, BERNARD, CHAINETTE, OXFORD, TURC and ETOILE", engraved on oval brass plates fixed with respect to the Damas correspondents.

GG

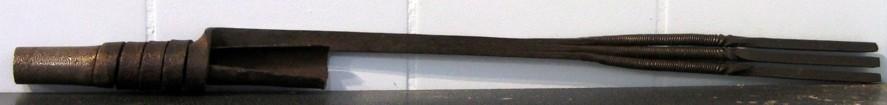

Wholesale plan, a superb example of barrel in Damas